Fabricated & Machined Parts

When You Need Them Most

The Process

Step One - Inquiry

Step Two - Strategy

In-House Fabrication

Local Outsourcing

Overseas Procurement

(based on lead-time, quality, cost, etc…)

Local Outsourcing

Overseas Procurement

(based on lead-time, quality, cost, etc…)

Step Three - Quote/Order

Fabrication

Equipment: Shear – Bandsaw – Drill Press – Mill – Welder – Etc

Materials

Welding

Grinding

Paint

Turntable Base

Panel Stand

Assorted Weldments

Pallets

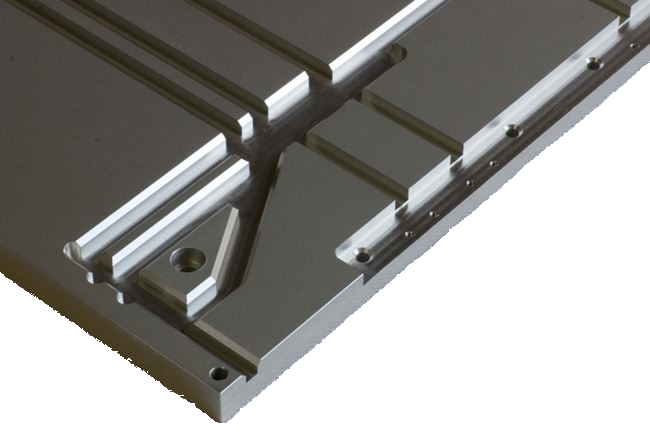

Machined Parts

Equipment: 5 Axis Bridge Mill – MC Center – CNC Mill – CNC Lathe – Brake – Drill Press – Etc

30×50 DOUBLE COLUMN MACHINE

X – axis : 5,200 mm (204.72 “)

Y – axis : 3,600 mm (141.72 “)

Z – axis : 800 mm (31.50 “)

W – axis : 1,200 mm (47.24 “)

X – axis : 5,200 mm (204.72 “)

Y – axis : 3,600 mm (141.72 “)

Z – axis : 800 mm (31.50 “)

W – axis : 1,200 mm (47.24 “)

Steel Parts

SUS Parts

Aluminum Parts

MC Nylon

Various Finishes

(Copper, Bakelite, Hard Chrome, Black Oxide, Diamond Coating, Etc)

Assembly

(End Effector Stand)

Assembly

(Turntable)

Assembly

(Jig Units)