We Build The Machine

…that builds the machine

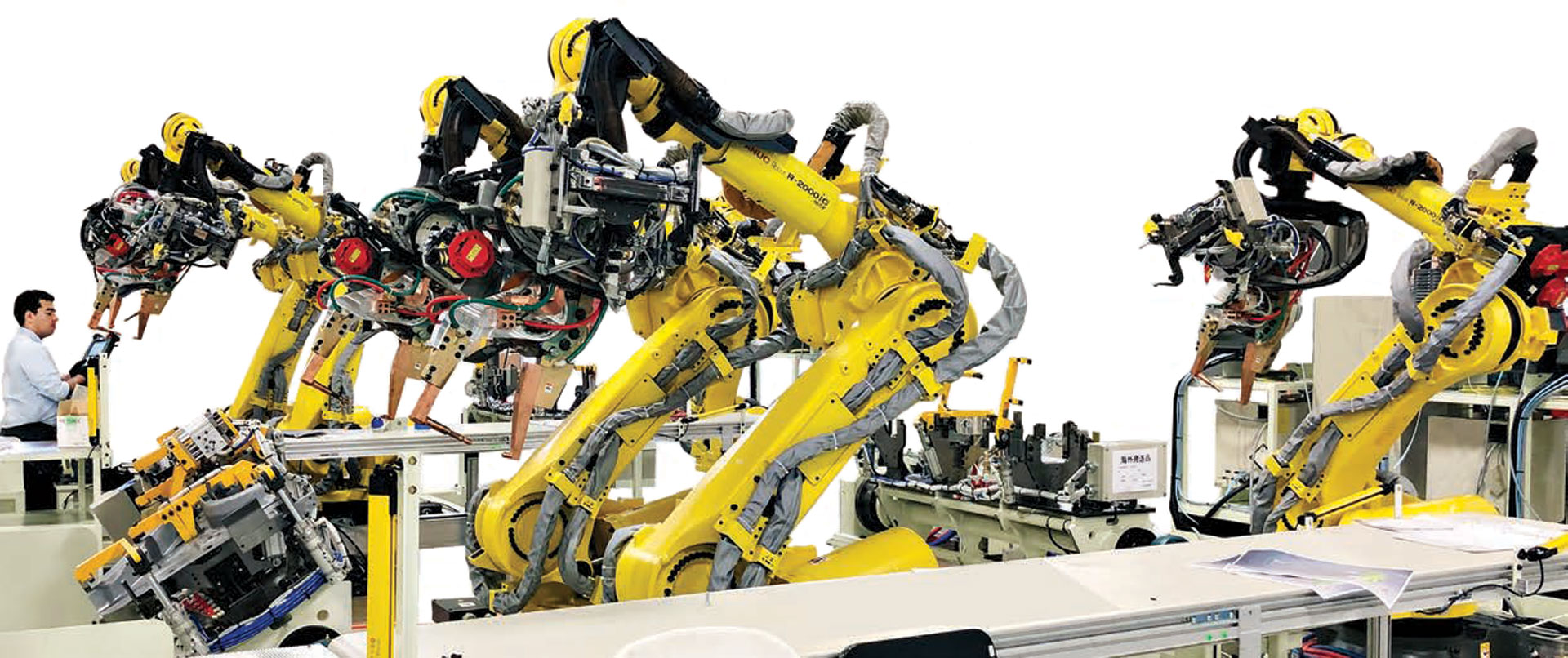

Since 2004, ASKA USA has been servicing the automotive industry of North America, providing high quality turnkey robotic spot welding, arc welding & handling applications to dozens of tier 1 & tier 2 manufacturing facilities in the United States & Canada. We understand the requirements for success in the world’s most demanding industry: an eye for detail, a nose for evaluating potential risks, a steady & experienced mind for analyzing complex processes and the steely resolve to meet aggressive deadlines. Our team is lean, but our resources are broad — both in North America at our parent company in Japan.

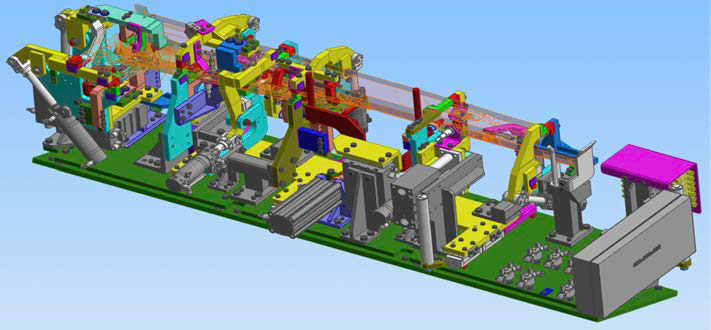

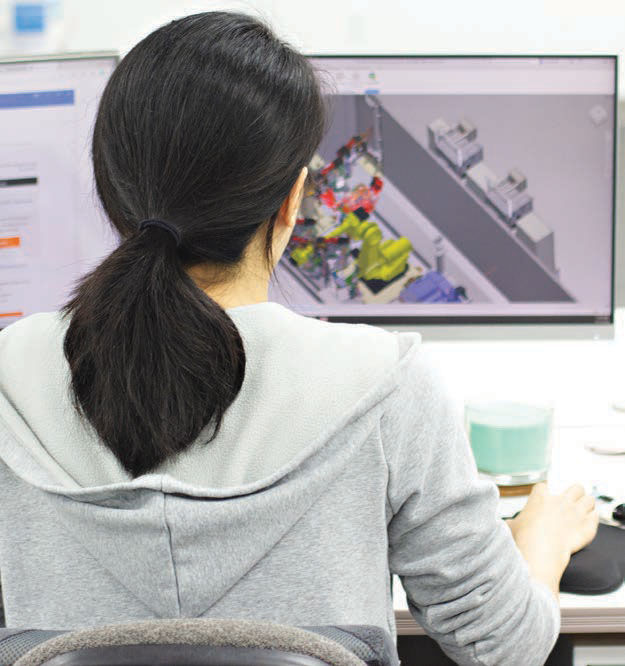

Mechanical Design

Meticulous | Inventive | Cost-Effective

3D Modeling

2D Blueprints

Robot Simulation / Layout Investigation / Offline Robot Teaching

Field Investigation / Quality Confirmation

Design Review

Software: Inventor, AutoCAD

Kaizen / Troubleshooting / Modification

2D Blueprints

Robot Simulation / Layout Investigation / Offline Robot Teaching

Field Investigation / Quality Confirmation

Design Review

Software: Inventor, AutoCAD

Kaizen / Troubleshooting / Modification

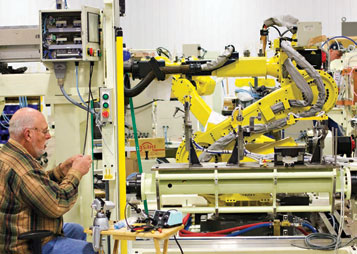

Electrical Design

Safety First | User-Friendly | Troubleshooting

Robots: Fanuc, Yaskawa, Panasonic, Daihen, Kawasaki, Nachi

PLC / HMI: Omron, Mitsubishi

Hardware & Software Design

Robot Teaching

Controls Enclosures Design & Build

PLC Programming / Integration / On-Site Debug / Remote Support

PLC / HMI: Omron, Mitsubishi

Hardware & Software Design

Robot Teaching

Controls Enclosures Design & Build

PLC Programming / Integration / On-Site Debug / Remote Support

Electrical Design

Safety First | User-Friendly | Troubleshooting

Robots: Fanuc, Yaskawa, Panasonic, Daihen, Kawasaki, Nachi

PLC / HMI: Omron, Mitsubishi

Hardware & Software Design

Robot Teaching

Controls Enclosures Design & Build

PLC Programming / Integration / On-Site Debug / Remote Support

PLC / HMI: Omron, Mitsubishi

Hardware & Software Design

Robot Teaching

Controls Enclosures Design & Build

PLC Programming / Integration / On-Site Debug / Remote Support

Fabrication & Machining

Precision | Quality | On Time

Okuma MCR-A5C2 30×50 5 Axis Double Column×1

Prototrak CNC Mill × 3 ( 60”,23”,20.5”)

Manual Mill × 1

Manual Lathe × 1

Horizontal Band Saw

Band Saw × 3

Drill Press × 2

Shear

Brake

Iron worker

Paint Booth

Faro Arm

Prototrak CNC Mill × 3 ( 60”,23”,20.5”)

Manual Mill × 1

Manual Lathe × 1

Horizontal Band Saw

Band Saw × 3

Drill Press × 2

Shear

Brake

Iron worker

Paint Booth

Faro Arm

Equipment List

Welding

Small Part Machining

Large Frame Machining (Okuma)

Paint

Quality Confirmation (Faro Arm)

Small Part Machining

Large Frame Machining (Okuma)

Paint

Quality Confirmation (Faro Arm)